Hydraulic Cylinder

Hydraulic Cylinders manufacturer

Qualified hydraulic cylinder with enconomical costs

www.hc-hydraulic-cylinder.com

Hydraulic cylinder manufacturers--HC news

Apply patent for self-locking cylinder

In order to protect the intellectual property rights and standardize market order,HC hydraulic cylinder invite property rights experts to discuss the patent of our unique product,self-locking cylinder.It also help consumer to make a right choose and buy regular high quality products.Welcome pay attention to our products.

In order to protect the intellectual property rights and standardize market order,HC hydraulic cylinder invite property rights experts to discuss the patent of our unique product,self-locking cylinder.It also help consumer to make a right choose and buy regular high quality products.Welcome pay attention to our products.

Kewords :

Apply patent for self-locking cylinder

In order to protect the intellectual property rights and standardize market order,HC hydraulic cylinder invite property rights experts to discuss the patent of our unique product,self-locking cylinder.It also help consumer to make a right choose and buy regular high quality products.Welcome pay attention to our products.

In order to protect the intellectual property rights and standardize market order,HC hydraulic cylinder invite property rights experts to discuss the patent of our unique product,self-locking cylinder.It also help consumer to make a right choose and buy regular high quality products.Welcome pay attention to our products.

Kewords :

In order to develop HC Hydraulic Cylinder Co., Ltd. employees' professional skills and service, they received a broader training about self-locking hydraulic cylinder from Mr. Wang. After that training, they all feel experience quite deep and profit is very big.

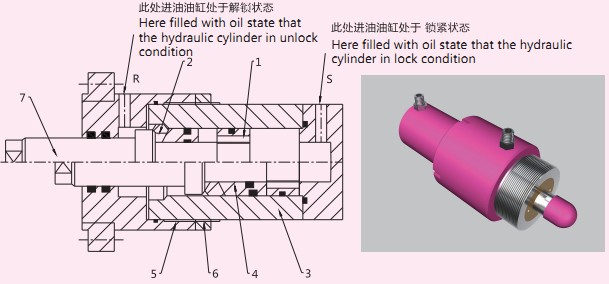

From these picture, we can find how self-locking hydraulic cylinder works. And help customer understand why self-locking hydraulic cylinder is much expensive than normal hydraulic cylinder. Choose hydraulic cylinder will cost about 20% less. But choose self-locking hydraulic cylinder will cost about 30% less. In addition, self-locking hydraulic cylinder will keep the products perfect without any flaw.

From these picture, we can find how self-locking hydraulic cylinder works. And help customer understand why self-locking hydraulic cylinder is much expensive than normal hydraulic cylinder. Choose hydraulic cylinder will cost about 20% less. But choose self-locking hydraulic cylinder will cost about 30% less. In addition, self-locking hydraulic cylinder will keep the products perfect without any flaw.

Kewords :

Gihan from Sri Lanka was visiting HC Hydraulic Cylinder Co., Ltd today, and place a big order to us .

he said: what a big company, and the people are very friendly and hard working. the products in the stock is very beautiful and the quality are pretty good. what a nice day.

he said: what a big company, and the people are very friendly and hard working. the products in the stock is very beautiful and the quality are pretty good. what a nice day.

Kewords :

self-locking hydraulic cylinder not only with best quality and competitive price, but also with many advantages than common hydraulic cylinder. so self-locking hydraulic cylinder becomes one of the best-selling products in HC.

welcome to contact us.

welcome to contact us.

Kewords :

hydraulic cylinder|self-locking hydraulic cylinder manufacturer

Why do we choose self-locking hydraulic cylinder for mould?

Self-locking hydraulic cylinder is a kind of cylinder that only for mould clamping, a

Self-locking hydraulic cylinder- sometimes also called locking cylinder is one of the most technical cylinders on this field. Self-locking hydraulic cylinder is very commonly used in the places where needs long time holding weight ,like under water 、single action 、load backward etc. locking cylinder especially used in mould clamping when need high clamping pressure. when locked ,Self-locking hydraulic cylinder can also stably and reliably used even there is no oil or pressure supporting. A Self-locking hydraulic cylinder can be widely used for electricity、construction、machinofacture、diggings、railway、jack etc.

Locking cylinder working principle:

A good locking cylinder usually has the bellowed characteristics:

1) No extra retaining mechanism

2) Ability of bearing tons of force

3) Clear locking pot

4) Easy installation

5) Good sealing

6) Reasonable design

7) Stroke depends on different requirements

Self-locking hydraulic cylinder manufacturers

There are many hydraulic cylinder manufacturers can make Self-locking hydraulic cylinder.Like Denison(America)、HPS(France)、Atos(Italy)、HC(China) Parker(America) etc. These companies all all offering Self-locking hydraulic cylinder, and with good quality but meanwhile with high price. So when the customers picking the lock cylinder they need to meet their purchase level, because compare to other normal hydraulic cylinder. This price of this kind of locking cylinder can be 5-10times even more higher at the same size.

Chinese locking cylinder manufacturers

There are not too many famous hydraulic cylinder manufacturers in China, but still can find some good companies that can do pretty good job on this field, such as SUNTER、HC、Vege etc. There are not too many Chinese lock cylinder that has occupied the world market but as the world is getting accept the quality that “made in China” and products from China is so much cheaper than other market of locking cylinder as well as most of products. China will become the biggest locking cylinder market in a very short period for sure. Under this circumstance, Chinese locking cylinder manufacturer have to focus on new technology and high quality to enlarge the market on the whole world.

Although a locking cylinder can be much more expensive than other kind of hydraulic cylinder, but take the technology and its good characters it is more than worthy to invest more .but customers still need to pay attention on picking good locking cylinder for their products.

Why do we choose self-locking hydraulic cylinder for mould?

Self-locking hydraulic cylinder is a kind of cylinder that only for mould clamping, a

Self-locking hydraulic cylinder- sometimes also called locking cylinder is one of the most technical cylinders on this field. Self-locking hydraulic cylinder is very commonly used in the places where needs long time holding weight ,like under water 、single action 、load backward etc. locking cylinder especially used in mould clamping when need high clamping pressure. when locked ,Self-locking hydraulic cylinder can also stably and reliably used even there is no oil or pressure supporting. A Self-locking hydraulic cylinder can be widely used for electricity、construction、machinofacture、diggings、railway、jack etc.

Locking cylinder working principle:

A good locking cylinder usually has the bellowed characteristics:

1) No extra retaining mechanism

2) Ability of bearing tons of force

3) Clear locking pot

4) Easy installation

5) Good sealing

6) Reasonable design

7) Stroke depends on different requirements

Self-locking hydraulic cylinder manufacturers

There are many hydraulic cylinder manufacturers can make Self-locking hydraulic cylinder.Like Denison(America)、HPS(France)、Atos(Italy)、HC(China) Parker(America) etc. These companies all all offering Self-locking hydraulic cylinder, and with good quality but meanwhile with high price. So when the customers picking the lock cylinder they need to meet their purchase level, because compare to other normal hydraulic cylinder. This price of this kind of locking cylinder can be 5-10times even more higher at the same size.

Chinese locking cylinder manufacturers

There are not too many famous hydraulic cylinder manufacturers in China, but still can find some good companies that can do pretty good job on this field, such as SUNTER、HC、Vege etc. There are not too many Chinese lock cylinder that has occupied the world market but as the world is getting accept the quality that “made in China” and products from China is so much cheaper than other market of locking cylinder as well as most of products. China will become the biggest locking cylinder market in a very short period for sure. Under this circumstance, Chinese locking cylinder manufacturer have to focus on new technology and high quality to enlarge the market on the whole world.

Although a locking cylinder can be much more expensive than other kind of hydraulic cylinder, but take the technology and its good characters it is more than worthy to invest more .but customers still need to pay attention on picking good locking cylinder for their products.

Kewords :

Good News !

HC Hydraulic Cylinder Co., Ltd. is going to attend 13th China Dongguan International Machinery&Materials Exhibition

HC Hydraulic Cylinder Co., Ltd. is going to attend 13th China Dongguan International Machinery&Materials Exhibition

Kewords :

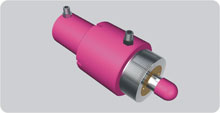

Self-locking cylinder

HC self-locking cylinder

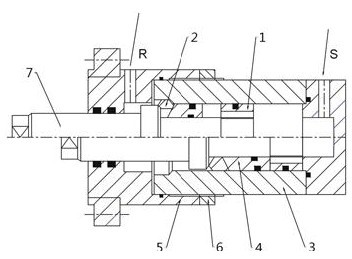

Since the pressure is too large when many die-casting in feeding, cause the hydraulic cylinder back. HC designed and developed a self-locking cylinder device to solve this problem.

The self-locking cylinder consist of cylinder tube, front housing, back housing, piston and piston rod. The connection of front housing and back housing with the cylinder tube is thread.

HC self-locking cylinder standard bore: 40 mm, 50 mm, 63 mm. The standard length of the piston rod is in 100 mm.

The working principle of self-locking cylinder: Without lock block condition, the self-locking cylinder would not move back. So the self-locking cylinder can bear the pressure form the die casting, and the self-locking cylinder would not move back.

The self-locking cylinder is locked when the oil comes inside form the“S” port. Then the piston moves backward under the oil pressure. The self-locking cylinder will locked automatically. And the self-locking cylinder is unlocked when the oil comes inside from the“R” port.

HC self-locking cylinder advantage:

1. No extra locking mechanisms

2. Can bear more than ten tons of pressure

3. No additional action

4. Locking point clear

5. Easy to install

6. Well-sealed

7. Well-designed

8. Custom travel as needed

HC hydraulic cylinder Co., Ltd has many years of self-locking cylinder production experience. Using self-locking cylinder can greatly reduce the cost of tooling and processing.

Kewords :

Self-lock hydraulic cylinder

As is known to all, hydraulic cylinder is widely used for every walk of life. And people always use traditional hydraulic cylinder to production and so on.

Here I show our self-lock hydraulic cylinder to everybody. Self-lock hydraulic cylinder is a machine which needs to lift heavy weight without oil pressure. There is a lock nut to hold the piston. And it is much better than traditional hydraulic cylinder.

Why do I recommend this type hydraulic cylinder to you?

Because: 1. It doesn’t need additional locking mechanism and behavior;

2. It can bear over 10tons power;

3. Clear locks point;

4. Easy installation;

5. Excellent seal;

6. Reasonable design;

7. Stroke will be subject to your request.

Upon to the above reasons, self-lock hydraulic cylinder is widely used in electricity, structure, machinofacture, mine, Railroad Bridge, shipbuilding and other trades. HC hydraulic cylinder is always popular in its stable performance and reliable quality. And we have won an excellent reputation in international markets. Kewords : self-lock

Self locked cylinder, including cylinder block, cylinder piston working cavity with the top up, top-up along the axial piston fixed on the face there can be piercing at the top end cap of the cylinder piston rod, piston rod back position with the oil chamber, oil chamber upper back bit with the piston, the piston back to the lower end position along the axial piston fixed a bit back, back to the position along the axial piston rod through the bottom of the piston and the cylinder of fixed connected with the top cover up out of the cylinder along the axis, the cylinder body has a lock cylinder, sleeves, and a number of lock blocks, the top face on the sleeve of a gland, the lateral wall of the sleeve and coherent picture tube body wall, along the axial piston rod through a number of lock blocks, each block is under lock and unlock the piston end face on the match, each locking block on the face and the lower surface of plate paste, between the top plate and a compression spring as described gland, gland fixed at the upper end of the cylinder. The aim is to provide a lifting of heavy objects was to prevent the decline of self-gravity self locked cylinder.

Kewords :