Hydraulic Cylinders manufacturer

Qualified hydraulic cylinder with enconomical costs

www.hc-hydraulic-cylinder.com

Hydraulic cylinder manufacturers--HC news

Skype: anole-hc-02

MSN: anole-hc-02@hotmail.com

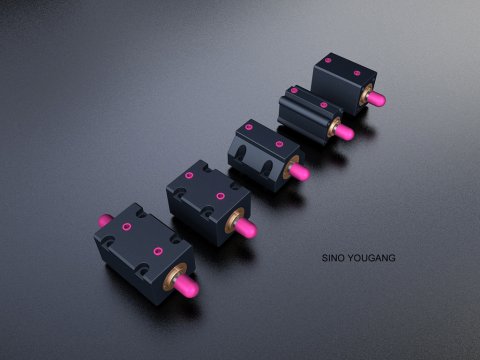

Square hydraulic cylinder can also produce double action hydraulic cylinder.This file will talk about the advantage of square hydraulic cylinder and the hydraulic cylinder type.HC hydraulic cylinders longking for your enquiry.

The advantages of Square hydrailic cylinder:

1. Save installation space, the total lenght of the hydraulic cylinder is equal to the 1/2 of the cylinder with the same bore and the same stroke.

2. Installed directly, without any accessories.

3. Apply to mould, processing fixture or installation space of limited machine occasion.

4. Another type:reaction type and without rotating type.

The square hydraulic cylinder support installation:LA,SD,a former oil plate,plate after oil

Square hydraulic cylinder standard cylinder bore range are 30,40,50,63,80

stroke can be customized according to customer requirements,If you require the hydraulic cylinder stroke more than 100 mm,

please contact to our sales department.

written by Tina

skype:anole-01

service1003@hc-hydraulic-cylinder.com

www.hydraulic-cylinders-supplier.com

Temperature rise in hydraulic cylinder will shorten the using life of hydraulic cylinder.

Followed is the reason for temperature rise in hydraulic cylinder.

1. The volume of cylinder block is too small to eliminate heat efficiently. There is no cooling facility or it is too small and lead to temperature rise in hydraulic cylinder.

2. We often choose the oil supply system according to the oil flow speed. There will be a large amount redundant oil flow back to the valve in high voltage when working and it will cause

3. Temperature rise in hydraulic cylinder cause by the damage of unloading return circuit. Hydraulic cylinder could not unload when stop working. The all oil will flow under high voltage, and it will produce heat.

4. The pipe is the system may be too thin or too long, it will cause overmuch pressure loss .

5. The bad quality of spare parts will also cause temperature rise in hydraulic cylinder. Because of the poor precision, mechanical friction will produce luxuriant heat.

6. The fit clearance between fitting pieces is too small and may lead to temperature rise in hydraulic cylinder.

7. The high working pressure will cause temperature rise in hydraulic cylinder. The working pressure in hydraulic cylinder is higher than it needed. For the sealing device is too tight or damaged, we have no alternative but adjust the working pressure to a higher level.

8. The working condition is too high and lead the temperature rise in hydraulic cylinder.

9. Improper selection of hydraulic oil. The thick viscosity will cause more effective resistance. Otherwise, the thin viscosity will cause leakage. All of these will lead to temperature rise in hydraulic cylinder.

10. There has blocking in liquid inlet and make high speed flow, and then lead to temperature rise in hydraulic cylinder.

These ten are the main reason for temperature rise in hydraulic cylinder. Hope every custom can find reason from here and solve the problem of temperature rise in hydraulic cylinder.

Web:http://www.hc-hydraulic-cylinder.com

http://www.anole-hot-runner.com

http://www.hot-runner-system.com

Written by: Cherry

Eml: service1002@anole-hot-runner.com

Hydraulic oil use matters needing attention: Statistics indicated that 70% hydraulic system breakdown is because uses improper. Therefore,in order to guarantee the hydraulic system normally and works reliably, not only need choose the hydraulic oil correctly, moreover must use and manage the hydraulic oil correctly. In the use, should pay attention to prevents the hydraulic oil be polluted, replaces the hydraulic fluid promptly.

1st, maintains hydraulic system's clean, hydraulic element processes and impurities and so on iron filings metal powder in the installation process survives, if not be cleaned, will lead in the oil, also along with the oil flowing, the impurity will cause the hydraulic system work abnormal, will be serious will create the breakdown. Therefore, the hydraulic system before installing movement, should inspect and clean carefully, no matter after is new perhaps the overhaul hydraulic system, as well as when replacement hydraulic fluid certainly must clean, the clean hydraulic system easiest to use hydraulic unit uses originally the power oil or tries the machine oil.

2nd, prevents the moisture content to mix in the hydraulic fluid. after mixing in the moisture content, the hydraulic fluid can emulsify becomes the cream color, should trade the oil promptly, in order to avoid creates hydraulic element's attrition, the corrosion, causes the hydraulic system operation worsening. The hydraulic system mixes in the moisture content the way is mainly the fuel tank and the chiller,periodic inspection rack's oil box cover whether to seal, whether the chiller does enter the water, the periodic cleaning filter, approximately every three months clean one time.

3rd, regular replacement hydraulic oil, hydraulic oil in use, as a result of the deterioration and by foreign substance's pollution, will be caused the quality to drop, when after the quality drop surpass certain limit, the hydraulic oil needs to replace. Hydraulic oil service life with its working condition and quality related, under the normal use and the management condition, includes the chemical additive hydraulic fluid, the service life is about generally one year. If including anti-oxygen, anticorrosion chemical additive, and uses the hydraulic fluid which three kind of base oil become well distributed, the service life may amount to one-and-a-half years to two years. Above trades the oil cycle is the common situation, because in fact some equipment management maintenance work can complete, the hydraulic fluid use cycle may also lengthen period of time, this also decided according by equipment use frequency.

If you want to know more information about hydraulic system and hydraulic cylinder,please contact at

service2@hc-hydraulic-cylinder.com

material of cylinder barrel

Hydraulic cylinder's function must turn the hydraulic oil pressure into mechanical energy.The hydraulic cylinder consists of cylinder tube, cylinder cover,piston,piston rod,sealing device,cushioning device,exhaust. Today ,i focus on the material of cylinder barrel.

material of cylinder barrel

The material of cylinder barrel is Carbon steel C45.Carbon steel the earliest and highest demand basic material in modern industry. Because the cost of the material barrel is reasonable and its also useful. At presnt, Carbon steel output accounted for more than 80% in each country.It is widly used in building,railroad,vehicle and many kinds of machine-made industry.But it can be gradually oxidized in air.This is the short point of the material of cylinder barrel or cylinder tube.Therefore,we often chroming the piston rod to get the rid of rust and increasing the hardness of the surface of piston rod.Bsides,the thickness of chromeplate is about two .

By extension,we adopt the brass as the material of copper bush.In order to protect the piston rod from scratch.The material of copper bush is wear resisting.Thistime we talk the information about the material of cylinder barrel.If you need some other information Please click here :http://www.hydraulic-cylinder-manufacturer.com/

Sharon

SHYPE: anole-hc-03

EMAIL: service1@hc-hydraulic-cylinder.com

MSN :anole-hc-03@hotmail.com

HC is the famous hydraulic cylinder supplier in china,we provide hydraulic cylinder parts,hydraulic cylinder and hydraulic sysytem.,hydraulic cylinder structure detail is more important for hydraulic cylinder disassembling.

This file will introduce hydraulic cylinder disassembling detail,hope can be helpful for you when you use the hydrauli cylinder.

(1)Before remove the hydraulic cylinder,should make hydraulic discharging pressure.Otherwise, when the hydraulic cylinder which connected to the hose connector is loosen,circuits oil of high pressure will spurt out quickly. Hydraulic circuits when discharging pressure shall loosen relief valve of the place first.Such as the handwheel or pressure regulating screws, the pressure oil unloading, then cut off power supply or cut off power supply, make the hydraulic device stop working.

(2)Should prevent to injury threads when removing, the piston rod top threads and piston rod surface,cylinder inwall, and etc.In order to prevent the piston rod and slightness piece bending or deformation, place mat wood application in supporting balanced.

(3)When remove should in turns, Because all hydraulic cylinder structure and size is not the same, remove in turns are also differ slightly. Generally should put off hydraulic cylinder oil of two cavities,then remove the cylinder head, finally remove the piston and the piston rod.

(4)Discharge before and after discharge should try to create conditions to prevent hydraulic cylinder part is polluted by the dust and impurities around. For example, remove should on the clean environment as far as possible; Remove all the parts after with plastic cloth cover, don't use cotton cloth or other work covered with a cloth.

(5)Hydarulic cylinder should be carefully examine the disassembly to determine what parts can continue to use, can repair and what parts of the reoccupy after, what parts must be replaced.

(6)Before assembly of each parts must be careful cleaning.

(7)Correct installation of sealing device everywhere.

Hydraulic cylinder disassembling,we have more knowledge to learn to make our hydraulic cylinder long time to use.

If you demand for mould hydraulc cylinder,welcome to click: www.hydraulic-cylinders-supplier.com

Written by Tina

service1003@hc-hydraulic-cylinder.com

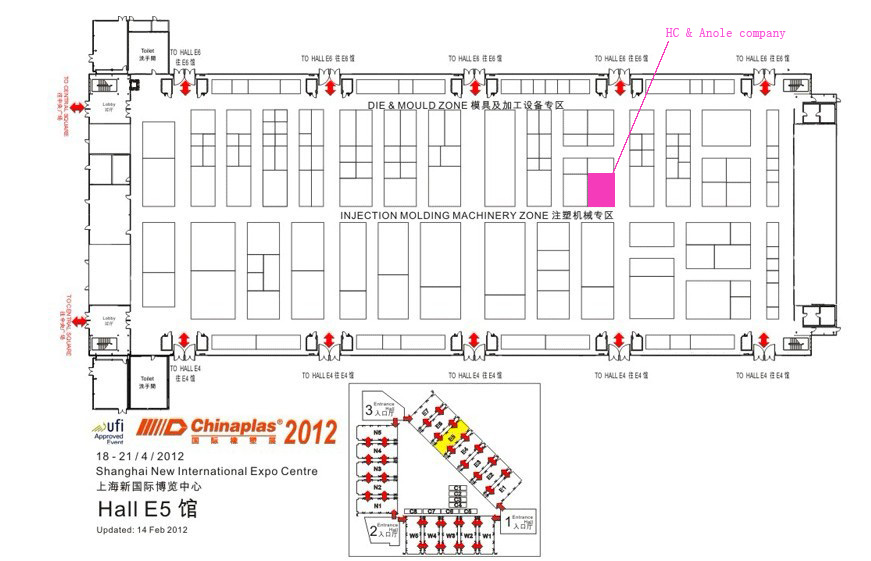

Hydraulic cylinder for Chinaplas 2012, Shanghai

Hydraulic cylinder for Chinaplas 2012, Shanghai,hydraulic cylinder for Chinaplas 2012, Shanghai, China,hydraulic cylinder exhibition,Chinaplas exhibition 2012, Shanghai, China-HC,Chinaplas 2012 location-HC

written by: Candy

email: service5@anole-hot-runner.com

Skype: anole-hc-02

MSN: anole-hc-02@hotmail.com

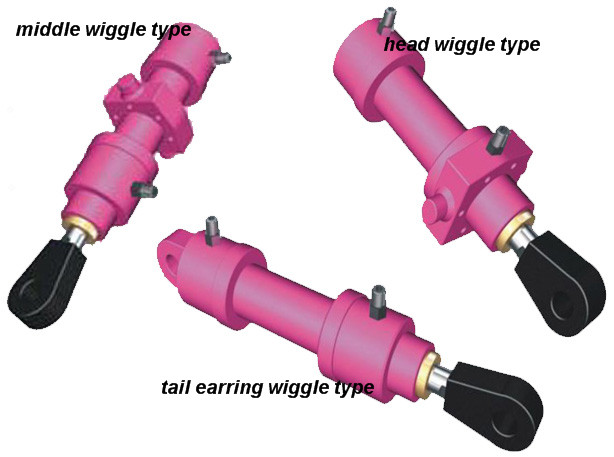

installation of adjustment of hydraulic cylinder stroke

installation of adjustment of hydraulic cylinder stroke main used in physical properties test of metal materials.The characterisics are that we set a adjustment rod on the top of the hydraulic cylinder 's cover and the adjustable bolt stand up to the adjustment rod.

The steps of installation of adjustment of hydraulic cylinder stroke

When you need to increase the stroke of piston rod,you should anticlockwise spin the adjustable bolt. At the same time adjustment rod will move right because it influenced by oil pressure and reset pressure .In contrast,when you want to cut the stroke of piston rod ,you should clockwise spin.Meanwhile,adjustment rod will movleft because it influenced by adjustable bolt pressure

.

This invention through the installation of adjustment of hydraulic cylinder stroke to achieve effective control of testing machine in order to provide more details and accurate test data.

Contact to: Sharon

Email: service1@anole-hot-runner.com

MSN: anole-hc-03@hotmail.com

Skype:anole-hc-03

http://www.anole-hot-runner.com

http://www.hc-hydraulic-cylinder.com

Hydraulic cylinder using attention:1. Before hydraulic cylinder working, it must be moved back and forth more than once. We shouldn’t use it until the air is pressed out of hydraulic cylinder completely. In order to avoid oil leakage, the oil entrance and outlet should be confirm with joint tightly by spacer.

Hydraulic cylinder using attention:2. Hydraulic cylinder should avoid leaving unused for a long time. If have to, we should operate it regularly and make its every part lubricating to avoid the working surface rusting

Hydraulic cylinder using attention:3. When hydraulic cylinder broken and need maintenance, we should move the piston to the bottle of cylinder. Beating during tearing town is forbidden.

Hydraulic cylinder using attention:4. When used nonflammable water-based hydraulic oil as working medium, the importer should state particularly so as to match special seal.

Hydraulic cylinder using attention:5. In order to insure the using life of hydraulic cylinder, the medium couldn’t contain impurity. Otherwise, the cylinder barrel will damaged and eventually result in hydraulic cylinder leakage. The precision of filter should be no fewer than 80μm.We should keep the hydraulic oil clean, check the hydraulic oil performance regularly and replace it if necessary.

Hydraulic cylinder using attention:6. Before tearing down, we should let the system unloaded, cut off the oil source.

Hydraulic cylinder using attention:7.It is recommended that the viscosity of the oil should be 10~110cSt(1。8~15E),ISOVG46.The temperature of the oil should between10 and 70 degree in regular work. It is best to select the lower viscosity oil when the the working temperature is low.

Hydraulic cylinder using attention:8. After hydraulic cylinder installation is finished, we should print lubricating oil on the relative motion parts before test run.

Hydraulic cylinder using attention:9. To ensure the regular working of hydraulic cylinder, there must have releaser. We must take pressure source and pressure loss into consideration when select the cylinder bore, piston rod bore and working pressure.

Contact:Cherry

E-mail:service1002@anole-hot-runner.com

Hydraulic cylinder using attention:1. Before hydraulic cylinder working, it must be moved back and forth more than once. We shouldn’t use it until the air is pressed out of hydraulic cylinder completely. In order to avoid oil leakage, the oil entrance and outlet should be confirm with joint tightly by spacer.

Hydraulic cylinder using attention:2. Hydraulic cylinder should avoid leaving unused for a long time. If have to, we should operate it regularly and make its every part lubricating to avoid the working surface rusting

Hydraulic cylinder using attention:3. When hydraulic cylinder broken and need maintenance, we should move the piston to the bottle of cylinder. Beating during tearing town is forbidden.

Hydraulic cylinder using attention:4. When used nonflammable water-based hydraulic oil as working medium, the importer should state particularly so as to match special seal.

Hydraulic cylinder using attention:5. In order to insure the using life of hydraulic cylinder, the medium couldn’t contain impurity. Otherwise, the cylinder barrel will damaged and eventually result in hydraulic cylinder leakage. The precision of filter should be no fewer than 80μm.We should keep the hydraulic oil clean, check the hydraulic oil performance regularly and replace it if necessary.

Hydraulic cylinder using attention:6. Before tearing down, we should let the system unloaded, cut off the oil source.

Hydraulic cylinder using attention:7.It is recommended that the viscosity of the oil should be 10~110cSt(1。8~15E),ISOVG46.The temperature of the oil should between10 and 70 degree in regular work. It is best to select the lower viscosity oil when the the working temperature is low.

Hydraulic cylinder using attention:8. After hydraulic cylinder installation is finished, we should print lubricating oil on the relative motion parts before test run.

Hydraulic cylinder using attention:9. To ensure the regular working of hydraulic cylinder, there must have releaser. We must take pressure source and pressure loss into consideration when select the cylinder bore, piston rod bore and working pressure.

Contact:Cherry

E-mail:service1002@anole-hot-runner.com