Hydraulic Cylinders manufacturer

Qualified hydraulic cylinder with enconomical costs

www.hc-hydraulic-cylinder.com

Hydraulic cylinder manufacturers--HC news

Hydraulic cylinder trouble removal

Removal methods:

a. air discharged through vent valve.

b. check whether the air intakes from the seals or not. If yes, change the seals.

Such as big vibration noisy, pressure fluctuation seriously, meet a block when the pump rotation, seizure slightly.

Removal methods can as per relevant books.

Removal method: enlarge single valve orifice.

Removal method:

as per relevant content.

removal method:

change rubber.

written by: Candy

Skype: anole-hc-02

Email: service5@hc-hydraulic-cylinder.com

l,hydraulic element often have the decisive influence in hydraulic system's divulging. This decided that our technical personnel in the new product design,old product's improvement,in the choose of cylinder, pump, pipe accessory, seal and hydraulic pressure auxiliary, elect superiorly in line with good, superior to choose with inexpensive principle prudent, comparison advance.

2nd, reasonable design fitting surface and packing surface: When the valve group or the pipeline fix on the fitting surface, obtain the satisfaction initial seal and prevent the seal to squeeze out the trench to be worn, the fitting surface must be straight, the packing surface request precision work, the surface roughness must achieve 0.8μm, flatness must achieve 0.01/100mm. The surface cannot have the radial direction scratch, connection screw's pretightening up force must be big enough, prevents the superficial separation.

3rd, in production and transportation process, must prevent the essential superficial clash, scratches. assembles the debugging process monitoring strictly, guarantee quality assembly.

4th, do not fall careless to some hydraulic system's revelation hidden danger, must perform to remove.

Plan two: Reduced impact and vibration: Hydraulic system's divulging which in order to reduce attack and vibrate the pipe connection which causes leak, may take the following measure:

①To use absorption of shock support fixed all pipes in order to absorb the impact and the vibration;

②Uses valve or the accumulator lowly reduces the impact;

③Suitable arrangement pressure control valve protective system's all parts;

④Reduced the quantity of pipe connection's use, the pipe connection uses the weld joint as far as possible;

⑤Uses the straight screw connector, the duplex fitting and the bend replaces the awl pipe thread attachment;

⑥Uses the oil discharge block to replace each tubing as far as possible;

⑦In view of the use top pressure, stipulated installs when uses bolt's torque and the caulking torque, prevents the junction plane and the seal is nibbled;

⑧Installs the pipe connection correctly.

Plan three: reduce seal attrition moves: The majority moves seal with precisely designs, if moves seal processing to be qualified, the installment is correct, the use is reasonable, may guarantee the long time relative non-divulging work. As for the design angle, the designer may use the following measure to lengthen moves seal life: 1st, eliminates the connecting rod and the drive shaft seal on load side;

2nd, with the dust ring, the safety mask and the oak gum cover protection connecting rod, prevents impurities and so on grinding compound, dust to enter;

3rd,select appropriate filtrating equipment and is advantageous for clean the fuel tank to prevent the dust to accumulate in the fat liquor;

4th, causes the connecting rod and the axis speed as far as possible low.

Plan four: To static seal request: The static seal prevents outside the fat liquor between the rigid fixing surface to release. The reasonable design seal groove size and the common difference, after the installment has distortion the seal to certain extrusion in order to pad the mating surface microscopic hollow, and enhances the seal internal stress higher than the seals pressure. When the components rigidity or the bolt pretightening up force are not very big, the mating surface will separate under the fat liquor pressure function, creates the gap or enlarges as a result of the sealing surface not very even and possibly from starts on the existence gap. Along with mating surface's movement, the static seal became has moved the seal. The rough mating surface will wear the seal, the change gap will nibble the seal edge.

Plan five: The control oil temperature prevents the seal deterioration: The seal premature deterioration possibly causes by many kinds of factors, an important attribute is the oil temperature is excessively high. The temperature elevates every time 10℃, then the seal life will halve, therefore should design the highly effective hydraulic system or establish forced cooling equipment reasonably, will cause the best fat liquor temperature maintains at 65℃ below; The engineering machinery cannot surpass 80℃; Another factor possibly the compatible question of use fat liquor and packing material, should selects the hydraulic fluid seal pattern and material quality according to the instruction for user or the related handbook, solves the compatible problem,extension the seal service life.

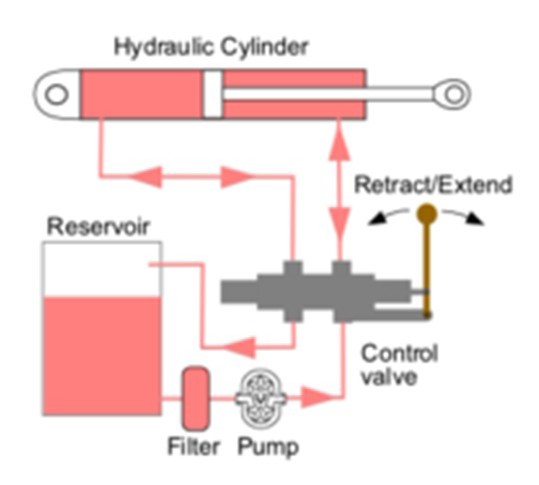

Hydraulic system have the advantages of small volume, light weight, large power, steady operation and can regulate speed. Hydraulic cylinder had widely used in various cranes. But hydraulic cylinder leakage is a troublesome problem .Now let us learn hydraulic cylinder leakage reasons and solutions.

Hydraulic cylinder leakage can be divided into internal leakage which caused by seal device leakage and external leakage which caused by cylinder block broken. Generally speaking, the manufactures could ensure the quality of cylinder block. So internal leakage is the main reason of hydraulic cylinder leakage.

Hydraulic cylinder leakage reasons and solutions:

1. Reason: leakage caused by abnormal wear

Solution: There must have proper oil in the hydraulic cylinder oil pump .Oil filter and oil should be changed regular. Attention: keep hydraulic cylinder clean when tearing off and assembling.

2. Reason: The seal are squeezed out and then result in hydraulic cylinder leakage.

Solution: Don not load unbalanced, make sure every parts’ lubricating during installation.

3. Reason: Hydraulic cylinder leakage reason is low temperature and harden.

Solution: Pay attention to keep the machine warm, do not operate it when the temperature is too low.

4. Reason: Because of the damage and fault of the sliding surface

Solution: Do not load unbalanced (especially for the hydraulic cylinder block).It must be painted by rust preventer during left with. Do not hit it.

5. Reason: Hydraulic cylinder leakage reason is container damage and fault

Solution: Do not produce loan on its maximum protraction as far as possible. We should leave some leeway of power when selected the machine.

Here I have make a brief introduce about hydraulic cylinder leakage reasons, and some solutions about hydraulic cylinder leakage. Hope the customers could recognize hydraulic cylinder leakage reasons and avoid hydraulic cylinder leakage.

Hydraulic system have the advantages of small volume, light weight, large power, steady operation and can regulate speed. Hydraulic cylinder had widely used in various cranes. But hydraulic cylinder leakage is a troublesome problem .Now let us learn hydraulic cylinder leakage reasons and solutions.

Hydraulic cylinder leakage can be divided into internal leakage which caused by seal device leakage and external leakage which caused by cylinder block broken. Generally speaking, the manufactures could ensure the quality of cylinder block. So internal leakage is the main reason of hydraulic cylinder leakage.

Hydraulic cylinder leakage reasons and solutions:

1. Reason: leakage caused by abnormal wear

Solution: There must have proper oil in the hydraulic cylinder oil pump .Oil filter and oil should be changed regular. Attention: keep hydraulic cylinder clean when tearing off and assembling.

2. Reason: The seal are squeezed out and then result in hydraulic cylinder leakage.

Solution: Don not load unbalanced, make sure every parts’ lubricating during installation.

3. Reason: Hydraulic cylinder leakage reason is low temperature and harden.

Solution: Pay attention to keep the machine warm, do not operate it when the temperature is too low.

4. Reason: Because of the damage and fault of the sliding surface

Solution: Do not load unbalanced (especially for the hydraulic cylinder block).It must be painted by rust preventer during left with. Do not hit it.

5. Reason: Hydraulic cylinder leakage reason is container damage and fault

Solution: Do not produce loan on its maximum protraction as far as possible. We should leave some leeway of power when selected the machine.

Here I have make a brief introduce about hydraulic cylinder leakage reasons, and some solutions about hydraulic cylinder leakage. Hope the customers could recognize hydraulic cylinder leakage reasons and avoid hydraulic cylinder leakage.

Hydraulic cylinder tightness

In the hydraulic system, hydraulic cylinder tightness can prevent leak of cylinder and dust entering. Seals play the role of elements, namely seals.Leakage will pollute the machine,the environment and even give rise to malfunctioning machinery and equipment for personal accident. Leakage within the hydraulic system will cause a sharp drop in volumetric efficiency amounting to less than the required pressure can’t even work.

picture-hydraulic cylinder tightness

picture-hydraulic cylinder tightness

Invasive system dust particles can cause or exacerbate the hydraulic friction and wear components, and further lead to leakage.

Thus,hydraulic cylinder seals device and hydraulic cylinder tightness play an important role in hydraulic equipment. The reliability of its work and the working life how long it has is an important index to measure the good or bad of hydraulic system.

All about the information of hydraulic cylinder tightness in this blog is included.

Contact to: Sharon

Email: service1@anole-hot-runner.com

MSN: anole-hc-03@hotmail.com

Skype:anole-hc-03

Many reason will cause the hydraulic system breakdown, induces has three aspects:

First, equipment's mechanical breakdown, this includes the hydraulic system design unreasonable, the installment gap is not correct, the hydraulic element quality question, the seal selects and so on improper, causes the hydraulic system breakdown by these questions not to relate generally with the hydraulic fluid.

Second, the operate miss creates the hydraulic system breakdown, because this is refers to the hydraulic system operators operates improper creates in the normal work time, like the wrong make and break valve, sudden power source stop,operating temperature or the pressure are excessively high, makes up when the oil add the wrong oil quality, fuel tank oil level have been excessively low, emits the separation not promptly from the fuel tank base the water and so on. Because the operate miss creates the hydraulic system breakdown, is not the hydraulic fluid quality question creates, does not involve the hydraulic fluid mostly, but some may reflect from the hydraulic fluid mass variation.

Third, because the hydraulic fluid quality creates the hydraulic system breakdown, this mostly because chose the improper oil or has used the unqualified oil, also possible created by long working time of hydraulic oil or long time no replace.

Contact:Elyn

Email: service2@hc-hydraulic-cylinder.com

Hydraulic cylinder manufacturer always introduce hydraulic cylinder daily maintain or hydraulic cylinder daily maintenance to customers. Hydro cylinder maintenance plays an important role in using hydraulic cylinders. Here I show some hydraulic cylinder maintenance to you.

1. Adjust hydraulic system’s working pressure, speed, related overflow valve, speed control valve to needed number according to the designed working regulations. And then locked the adjusting screw to prevent loosen.

2. Should be regular check the install and laden connected parts, tighten fastener in time and add lubrication to the part of oiling in time. Check fastener’s sliding wire, bended and other members’ transformation, flaw and so on. once found will be dealt immediately.

3. Pay attention to the increase temperature of working medium. Normal temperature is always below 55 degree, the highest cannot over 80 degree. Once found the temperature increased suddenly or over temperature should check and find out the reasons to removal the fault.

4. Avoid using it in high temperature or using it for a long time. Or it will cause low speed of system and pressure decreased phenomenon.

5. Should constantly be monitoring hydraulic cylinder motion state. Once found speed decreased, crawled, shake, and so on should stop to check and repair soon.

6. Should be regular check the rod, if it has galling, unilateral broken, chromium coating dropped, you’d better stop and separate it and fix.

7. Should be regular check the connected space of hydraulic cylinders controller valve, guide sleeve or cylinder gland. In addition, whether leakage of dust rings or not. Pay attention to the rod motion phenomenon when it works. If it retraction very clear, should separate and check it. If the seals are in bad situation, please change them.

8. Keep hydraulic cylinder especially working space clean, prevent dirty get in. also clean the rod in order to avoid damage seals and moving members.

hydraulic cylinder daily maintain,hydraulic cylinder maintenance,hydraulic cylinder manufacturer,hydro cylinder maintenance,hydraulic cylinder daily maintenance

contact: Candy

email: service5@hc-hydraulic-cylinder.com

Introduction for hydraulic cylinder and pneumatic cylinder advantages and disadvantages,hope it wil be helpful for those who are using.

1.Generally speaking, since the pneumatic system using pressure is in 0.2 1.0 Mpa scope,so the pneumatic cylinder can not make the power of the high power component.But using hydraulic system,hydraulic cylinder can make as a large power component.

2.Consider the medium,air is inexhaustible, no cost and supply difficulties,can be used directly discharged into the atmosphere,It is convenient without pollution, but hydraulic oil is opposite.

3.Air viscosity is small, resistance is less than the hydraulic oil.

4. The air compression rate far surpass the hydraulic oil, so the stability and response aspects of working has sent far away. The hydraulic cylinder is the most important in hydraulic system of execution element, it can convert hydraulic energy to mechanical energy, and combine with all kinds of transmission agency, to finish all kinds of mechanical motion.The hydraulic cylinder advantage is simple in structure, big output, stable and reliable performance, easy operation and maintenance, wide range of application etc.

Introduced more than hydraulic cylinder and pneumatic cylinder advantages and disadvantages, and whether you clear?

Choose HC hydraulic cylinder, our company is your best choice and look forward to your arrival!

welcome to click this website: www.hydraulic-cylinders-supplier.com to view hydraulic cylinder you needed.

written by Tina

service1003@anole-hot-runner.com

molding hydraulic cylinder|hydraulic cylinder for injection moulds

HC offers our customers the best cost performance of molding hydraulic cylinder、molding hydraulic cylinders.hydraulic cylinders for injection moulds.all the HC molding hydraulic cylinder are produced according to international standard dimensions for ISO6020/22.Thus,our customer can get the products within a very short time and what's more importand is:this kind of molding hydraulic cylinder are very easy to replace when any spare parts fail.our customer can replce by themselves.

As when the moulds clamping.it needs a very high pressure to inject the parts.thus,molding hydraulic cylinder also need a very high performance on holding high pressure.which on the other hand,means hydraulic cylinder for injection moulds need a really good seal performance.HC knows this very clearly.we only used the best seal rings and o-rings to prevent the molding hydraulic cylinder from leakage .

If you want to ask question on hydraulic cylinder for injection moulds.please send bellow email:

service3@hc-hydraulic-cylinder.com

skype:anole-hc-01

msn:anole-hc-01@hotmail.com