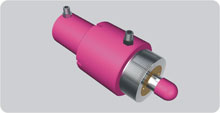

Hydraulic Cylinder

Hydraulic Cylinders manufacturer

Qualified hydraulic cylinder with enconomical costs

www.hc-hydraulic-cylinder.com

The general design step of the hydraulic cylinder

1) to grasp the raw data and design basis, including: the use of the host and working conditions; working bodies of the structural characteristics of the load conditions, stroke size and movement requirements; hydraulic system on the selected operating pressure and flow; materials, parts and processes of reality; relevant national standards and technical norms.

2) According to the action asked to select the host type and structure of the hydraulic cylinder form.

3) According to the hydraulic cylinders are exposed to the external load force, such as gravity, friction and external kinematic, inertial force and the work load, to determine the hydraulic cylinder on each stage in the itinerary changes of the load power and the need to provide value.

4) According to the hydraulic cylinder of the work load and work of selected oil pressure, determine the diameter of the piston and piston rod.

5) According to the velocity of the hydraulic cylinder, piston and piston rod diameter, determine the pump flow.

6) Select the cylinder material, calculate the diameter.

7) Select the cylinder head structure, calculation of the cylinder head and cylinder connection strength.

8) According to the work schedule requirements, determine the maximum working length of the cylinder L, typically L> = D, D for the rod diameter. As the piston rod slender, longitudinal bending strength should be checked and the stability of the hydraulic cylinder calculation.

9) When necessary, buffer design, exhaust and dust and other devices.

10) Draw the hydraulic cylinder assembly drawings and part drawings.

11) finishing the design calculations, approval drawings and other technical documents

Kewords :

2) According to the action asked to select the host type and structure of the hydraulic cylinder form.

3) According to the hydraulic cylinders are exposed to the external load force, such as gravity, friction and external kinematic, inertial force and the work load, to determine the hydraulic cylinder on each stage in the itinerary changes of the load power and the need to provide value.

4) According to the hydraulic cylinder of the work load and work of selected oil pressure, determine the diameter of the piston and piston rod.

5) According to the velocity of the hydraulic cylinder, piston and piston rod diameter, determine the pump flow.

6) Select the cylinder material, calculate the diameter.

7) Select the cylinder head structure, calculation of the cylinder head and cylinder connection strength.

8) According to the work schedule requirements, determine the maximum working length of the cylinder L, typically L> = D, D for the rod diameter. As the piston rod slender, longitudinal bending strength should be checked and the stability of the hydraulic cylinder calculation.

9) When necessary, buffer design, exhaust and dust and other devices.

10) Draw the hydraulic cylinder assembly drawings and part drawings.

11) finishing the design calculations, approval drawings and other technical documents

Kewords :