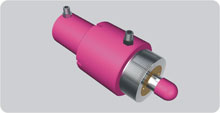

Hydraulic Cylinders manufacturer

Qualified hydraulic cylinder with enconomical costs

www.hc-hydraulic-cylinder.com

Hydraulic cylinder manufacturers--HC news

sole agent in Brazil

Istvan who comes from Brazil visit our company and would like to be our sole agent. He is not only interested in our products, but also like our electric items. We show him to our workshop, sample room, storage, etc.

The 13th China Dongguan International Machinery&Materials Exhibition

We start from company 9 am November 15th, 2011 and bring many samples of hydraulic cylinders, such as self-locking hydraulic cylinder, double-acting hydraulic cylinder and so on. We made our best efforts to prepare it. Everyone there must be with best service and highest technology.

Welcome to consultations.

Written by: Candy

Email: service5@hc-hydraulic-cylinder.com

This early morning,there is a huge troop made up of top leaders arrived in our company,they take a look at our producing department, storage,products showroom also visit administrative area.

They not only highly appreciated company principle,"Honesy,quality,responsibility",also urges safety in production.After several hours visit,they left with satisfied mood and went to visit other company.

Last few days, I got a phone from Jianjun Liu, he said, I know your company from website, and know you are one of the best companies production hydraulic cylinder in China. So I want to get some information about you. Then I send a form to him. After he got some basic information about our company, they can't wait to come to some on-site inspection. Just now, our general manager received them and have a happy talking.

As is known to all, Wirtgen Machinery Co., Ltd is a very famous machinery manufacturer. and their quality is always the best.

We are looking forward to cooperating with them.

Warmly welcome purchasing manager Jianjun Liu come and visit HC.

2) According to the action asked to select the host type and structure of the hydraulic cylinder form.

3) According to the hydraulic cylinders are exposed to the external load force, such as gravity, friction and external kinematic, inertial force and the work load, to determine the hydraulic cylinder on each stage in the itinerary changes of the load power and the need to provide value.

4) According to the hydraulic cylinder of the work load and work of selected oil pressure, determine the diameter of the piston and piston rod.

5) According to the velocity of the hydraulic cylinder, piston and piston rod diameter, determine the pump flow.

6) Select the cylinder material, calculate the diameter.

7) Select the cylinder head structure, calculation of the cylinder head and cylinder connection strength.

8) According to the work schedule requirements, determine the maximum working length of the cylinder L, typically L> = D, D for the rod diameter. As the piston rod slender, longitudinal bending strength should be checked and the stability of the hydraulic cylinder calculation.

9) When necessary, buffer design, exhaust and dust and other devices.

10) Draw the hydraulic cylinder assembly drawings and part drawings.

11) finishing the design calculations, approval drawings and other technical documents