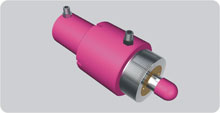

Hydraulic Cylinders manufacturer

Qualified hydraulic cylinder with enconomical costs

www.hc-hydraulic-cylinder.com

Hydraulic cylinder maintenance

Hydraulic cylinder maintenance

- Routine hydraulic cylinder maintenance

it's very important to have hydraulic cylinder maintenance and well protected in the daily using. here are several proposes

1.Regulate the range of cylinder barrel and the range of speed according to the working environment which was already determined when it is designed. interrelated spillover valve and governor valve should be locked with adjusting screw in the right position to prevent it from loosening.

2.Check the connection of installation and load position to see if the fastening piece is become flexible, if the lubricant is sufficient, if there has any component be out of shape or cracked. if any of above happens, it should be handled immediately.

3.Pay attention to the temperature of actuating medium, the range of temperature should be from 55℃ to 80℃.sudden change and out of range are unacceptable, the origins of the temperature anomaly must be located and rule out.

4.Avoid to run the equipment at high temperature, otherwise fault equipments may lead to low speed system and drawdown pressure.

5.Abserve working condition frequently, any drop off\crawl\shock will require immediate attention and halt to perform maintenance.

6.Inspect the cylinder rod for marred or worn sealing surfaces or exterior chromium shed, Replace any damaged or worn connections.

7.Examine junction surface of hydraulic cylinder and control valve, guide bush, junction of cylinder block and cylinder gland, wiper ring regularly. observe if there is any obvious retraction during cylinder rod's reciprocate. sealing elements must be replaced when it didn't work will.

8.Keep clean, especially working surface. The dirt in the cylinder rod needs to be eliminated in time. The entering of contamination will damage main running gear and sealing element

- Regular hydraulic cylinder maintenance

1.Make the bolts secure on a regular time schedule to avoid adrift related accident. the cycle is usually monthly.

2.Replace sealing element regularly, the period depends on the running conditions of hydraulic cylinder, sort of sealing element and manufacturer. the V-arrangement assembled sealing elements also needs to be adjust within a definite period of time to ensure machinery is in proper working condition.

3.Replace hydraulic fluid in time to make sure the cleanliness of system. According to the provisions hydraulic fluid needs to be filtered and the whole system (including cylinder block)should be rinsed.

4. hydraulic cylinder lump maintenance under the heading' hydraulic cylinder system' to administer. not only maintain the system, but also store the information such as changing hydraulic fluid, changing sealing element, strip inspection and perform maintenance in equipment technique file.