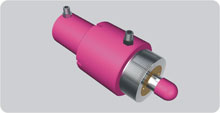

Hydraulic Cylinder

Hydraulic Cylinders manufacturer

Qualified hydraulic cylinder with enconomical costs

www.hc-hydraulic-cylinder.com

Precision injection technology be a driving force for plastic industry development

With the increasing demands for product appearance,electrical and electronic plastic parts become more complex in structure but also to keep the small size of the development. Precision injection molding technology in this area played a major role in the advanced precision molding technology greatly improves the quality of plastic parts, reliability, performance, reduce production costs and improve production efficiency, has great significance.

Injection technology is a method of manufacturing plastic products, the use of pressure injection of molten plastic into the plastic mold, cooling forming a variety of plastic parts you want to get a technical. Currently the most commonly used plastic is polystyrene. According to the International Mould & Plastic Hardware Industry Suppliers Association official Luo Baihui introduced, with the "3C" product development, precision injection molding precision injection molding machine as a key basic equipment, the size of the molding product repeatability, internal quality and repeatability and forming the three aspects of efficiency has been greatly improved. Compared to conventional injection molding equipment, precision injection molding machine really introduced for precise control products and precision production. Precision injection molding of plastics unit is to improve the quality of plastics, injection repeatability and quality of products within the three key components. Currently, the device mainly to the high-speed, high-voltage and fast response of the target development.

Kewords :

Injection technology is a method of manufacturing plastic products, the use of pressure injection of molten plastic into the plastic mold, cooling forming a variety of plastic parts you want to get a technical. Currently the most commonly used plastic is polystyrene. According to the International Mould & Plastic Hardware Industry Suppliers Association official Luo Baihui introduced, with the "3C" product development, precision injection molding precision injection molding machine as a key basic equipment, the size of the molding product repeatability, internal quality and repeatability and forming the three aspects of efficiency has been greatly improved. Compared to conventional injection molding equipment, precision injection molding machine really introduced for precise control products and precision production. Precision injection molding of plastics unit is to improve the quality of plastics, injection repeatability and quality of products within the three key components. Currently, the device mainly to the high-speed, high-voltage and fast response of the target development.