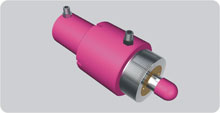

Hydraulic Cylinder

Hydraulic Cylinders manufacturer

Qualified hydraulic cylinder with enconomical costs

www.hc-hydraulic-cylinder.com

Hydraulic Cylinder Selection and Maintenance

Hydraulic Cylinder Selection and Maintenance

The hydraulic cylinder is mainly composed of the cylinder bore, rod, piston and cylinder head and end, seals, accessories and so on. And the cylinder bore, rod and piston is known as 3 major item of hydraulic cylinder.

The effection of hydraulic cylinder quality mainly to have three factors: designer experience, processing quality, use and maintenance.

A rich experience designer design hydraulic cylinders, must know the following parameters: (a). bore, rod and stroke dimensions (b). working pressure or oil cylinder loading (C). the temperature of working environment (d). work medium (e). Speed (f). other parameters, such as connecting forms and the ibore, rod and stroke of installment should better according to national standards or other standards, try best to avoid choosing non-standard sizes, or it will be difficulter in processing manufacturing cost.

The guide length is based on the stroke. And according to the working pressure or loading to checking the strength of cylinder, the piston rod, the screw, etc.

At the same time, work pressure, temperature, working medium and speed are the key to choose the seals. The different types of seals can bear different pressure, temperature, working medium and speed, water-glycol medium (HFC) can't use polyurethane sealing, can only use rubber seal; Sliping type seals is always used for rapid speed hydraulic cylinder, like Lancaster closure, Georgia to circle, GD1000K, TDI. Slower speed can use Yx type, U type, V type combined seals, etc.; Under the environment of high temperature and high pressure we should use fluoro rubber seals; Fast operation must considere useing cushion collar, cushion valve.

Kewords :